Chapter 5

Installation and Installation Tools

In addition to selecting the right kind of fastener, you need to choose the right installation approach, including the right tools.

You want to scale the installation system to the required task in order to optimize installation, maximize fastener performance, and promote cost-effective production.

Matching the right installation tools to the application ensures smooth, trouble-free installations. If you consider the installation equipment an integral part of the speed fastener system, you can be sure to have smoother production. Matching the right installation equipment to the job and to the fastener has a number of benefits:

-

It ensures a reliable fastener feed, which delivers higher speed.

-

You can cut assembly cycle times to one or two seconds.

-

Fast magazine reload times shorten production time even more.

-

It simplifies single-side assembly.

-

Matching the right tools to the fastener minimizes maintenance costs.

-

You can scale production to meet your needs, from low-volume batches to automated assembly lines.

There are three basic approaches to speed fastener installation. Each type of tooling is designed to accommodate different production levels and fastener volumes.

Power Tools

Ideal for low-power production (up to 250,000 per year), hand-operated power tools speed production and repairs. Avdel offers three hand-held pneumatic tool for speed fasteners:

7350 Hand-Held Pneumatic Tool - Lightweight and made of aluminum with an outer high-impact resistant nylon handle shell, the 7350 can install up to 1,500 fasteners per hour (with an average cycle time of two seconds). It has a high-capacity magazine, including a bowl-feed option to cut reloading time. It also features a long-reach barrel to get into tight places, and it can be mounted on a balancer.

7357 Hand-Held Pneumatic Tool - This is a lightweight, hand-operated speed fastener tool that has an average cycle time of one second to increase productivity. It is a pneumatic powered tool, making it more versatile and more powerful. The 7357 can handle the same range of fasteners and the same nose equipment as the 7530. It can also be mounted on a tool balancer for “top- down” assembly line use.

7357 Hand-Held Pneumatic Tool - This is a lightweight, hand-operated speed fastener tool that has an average cycle time of one second to increase productivity. It is a pneumatic powered tool, making it more versatile and more powerful. The 7357 can handle the same range of fasteners and the same nose equipment as the 7530. It can also be mounted on a tool balancer for “top- down” assembly line use.

7536 Hand-Held Pneumatic Tool - This pistol style tool is designed to handle the entire family of Avdel speed fasteners. It even comes with a control box and air cursor for small-diameter fasteners. To reduce shock, it uses hydraulics to dampen shock during speed fastener placement, and it uses the same common parts as the 7530.

7536 Hand-Held Pneumatic Tool - This pistol style tool is designed to handle the entire family of Avdel speed fasteners. It even comes with a control box and air cursor for small-diameter fasteners. To reduce shock, it uses hydraulics to dampen shock during speed fastener placement, and it uses the same common parts as the 7530.

7271 Hand-Held Pneumatic Tool - Made of lightweight aluminum with a protective blue PVC cover boot, this is an all-pneumatic high-performance tool designed for rapid, blind-side speed fastener installation. In addition to a two-second cycle time and high-capacity magazine, the unit also features an adjustable broach load using nylon stops. This allows accurate control of tool recoil and prevents mandrel damage.” The all-pneumatic design is highly reliable, eliminating the need for servicing hydraulic fluid and seals.

7271 Hand-Held Pneumatic Tool - Made of lightweight aluminum with a protective blue PVC cover boot, this is an all-pneumatic high-performance tool designed for rapid, blind-side speed fastener installation. In addition to a two-second cycle time and high-capacity magazine, the unit also features an adjustable broach load using nylon stops. This allows accurate control of tool recoil and prevents mandrel damage.” The all-pneumatic design is highly reliable, eliminating the need for servicing hydraulic fluid and seals.

Workstations

For medium-volume production from 250,000-1 million fasteners per year, Avdel offers three single-head workstations. These workstations can be adapted to almost any production process and are easy to operate with very little training, and they can handle the entire line of Avdel fasteners:

Pantograph Workstation - With the tool supported on an extendable arm, this workstation has a wide arm reach of more than 0.8 meters. It is designed for single-end operation and can be bench- or floor-mounted.

Pantograph Workstation - With the tool supported on an extendable arm, this workstation has a wide arm reach of more than 0.8 meters. It is designed for single-end operation and can be bench- or floor-mounted.

Fixed-Arm Workstation - This workstation supports the fastener tool in place on a fixed arm and features a foot pedal control for hands-free operation. It easily aligns with the workpiece, and the height of the arm is totally adjustable.

Fixed-Arm Workstation - This workstation supports the fastener tool in place on a fixed arm and features a foot pedal control for hands-free operation. It easily aligns with the workpiece, and the height of the arm is totally adjustable.

Underbench Workstation - To minimize space, this unit is mounted below the workbench to create more workspace. It also features a foot pedal control and is ideal for precision assembly of smaller components, complete with an integral safety guard.

Underbench Workstation - To minimize space, this unit is mounted below the workbench to create more workspace. It also features a foot pedal control and is ideal for precision assembly of smaller components, complete with an integral safety guard.

Assembly Workstations

For high-volume production (more than 1 million fasteners per year), Avdel offers multi-head workstations for faster assembly:

Mini-MAS - The Mini-MAS is a twin-head assembly station for parallel assembly. The fasteners are presented in pairs and can be used for various assembly applications. Hydraulic riveting modules make for shock-free assembly. The station is designed for seated users (a standing version is available) and activated by foot pedal for hands-free assembly.

Mini-MAS - The Mini-MAS is a twin-head assembly station for parallel assembly. The fasteners are presented in pairs and can be used for various assembly applications. Hydraulic riveting modules make for shock-free assembly. The station is designed for seated users (a standing version is available) and activated by foot pedal for hands-free assembly.

Multi-Head Assembly Workstations - Avdel offers multi-head workstations designed for synchronous placement of multiple fasteners. The workstation can be customized to handle 2-60 fasteners simultaneously. These units include diagnostics capabilities to improve quality control and facilitate maintenance, and they can be easily incorporated into most existing production facilities.

Multi-Head Assembly Workstations - Avdel offers multi-head workstations designed for synchronous placement of multiple fasteners. The workstation can be customized to handle 2-60 fasteners simultaneously. These units include diagnostics capabilities to improve quality control and facilitate maintenance, and they can be easily incorporated into most existing production facilities.

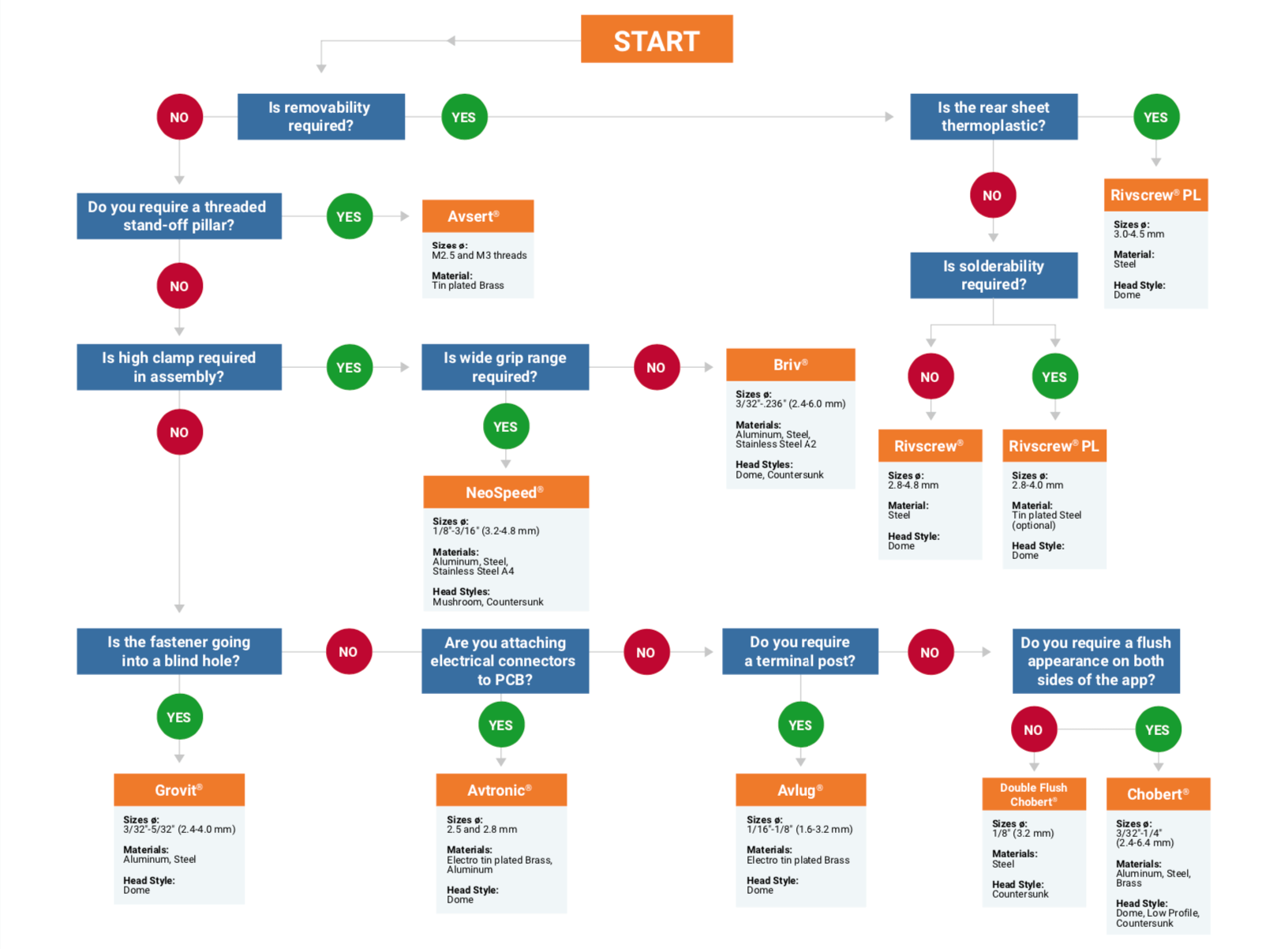

NeoSpeed

NeoSpeed Briv®

Briv®  Chobert

Chobert

Grovit®

Grovit®  Rivscrew®

Rivscrew®  Rivscrew PL

Rivscrew PL Avtronic

Avtronic Avsert

Avsert Avlug®

Avlug®

7357 Hand-Held Pneumatic Tool - This is a lightweight, hand-operated speed fastener tool that has an average cycle time of one second to increase productivity. It is a pneumatic powered tool, making it more versatile and more powerful. The 7357 can handle the same range of fasteners and the same nose equipment as the 7530. It can also be mounted on a tool balancer for “top- down” assembly line use.

7357 Hand-Held Pneumatic Tool - This is a lightweight, hand-operated speed fastener tool that has an average cycle time of one second to increase productivity. It is a pneumatic powered tool, making it more versatile and more powerful. The 7357 can handle the same range of fasteners and the same nose equipment as the 7530. It can also be mounted on a tool balancer for “top- down” assembly line use. 7536 Hand-Held Pneumatic Tool - This pistol style tool is designed to handle the entire family of Avdel speed fasteners. It even comes with a control box and air cursor for small-diameter fasteners. To reduce shock, it uses hydraulics to dampen shock during speed fastener placement, and it uses the same common parts as the 7530.

7536 Hand-Held Pneumatic Tool - This pistol style tool is designed to handle the entire family of Avdel speed fasteners. It even comes with a control box and air cursor for small-diameter fasteners. To reduce shock, it uses hydraulics to dampen shock during speed fastener placement, and it uses the same common parts as the 7530. 7271 Hand-Held Pneumatic Tool - Made of lightweight aluminum with a protective blue PVC cover boot, this is an all-pneumatic high-performance tool designed for rapid, blind-side speed fastener installation. In addition to a two-second cycle time and high-capacity magazine, the unit also features an adjustable broach load using nylon stops. This allows accurate control of tool recoil and prevents mandrel damage.” The all-pneumatic design is highly reliable, eliminating the need for servicing hydraulic fluid and seals.

7271 Hand-Held Pneumatic Tool - Made of lightweight aluminum with a protective blue PVC cover boot, this is an all-pneumatic high-performance tool designed for rapid, blind-side speed fastener installation. In addition to a two-second cycle time and high-capacity magazine, the unit also features an adjustable broach load using nylon stops. This allows accurate control of tool recoil and prevents mandrel damage.” The all-pneumatic design is highly reliable, eliminating the need for servicing hydraulic fluid and seals. Pantograph Workstation

Pantograph Workstation  Fixed-Arm Workstation

Fixed-Arm Workstation  Underbench Workstation

Underbench Workstation  Mini-MAS

Mini-MAS